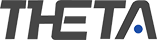

TLS-HT1330 stent laser cutting machine

Performance characteristics:

1. Compatible with multi brand fiber lasers: Suitable for high-performance fiber lasers of different brands and types, suitable for processing metal supports of various pipe diameters and lengths, with highly reliable and stable cutting quality.

2. Compatible with various laser cutting heads: suitable for laser cutting heads with different performance levels, including high, medium, and low, to meet various customer needs, while also being able to quickly switch between various laser cutting heads. Equipped with a CCD camera head, it has functions such as monitoring the status of the processing area, spot quality, and animation recording during the cutting process.

3. Natural granite platform design: Adopting a column structure, both the platform and columns use natural granite, and all axis systems are directly installed on the natural granite reference plane, with high accuracy and good stability.

4. Design of precision two-dimensional motion platform: Equipped with direct drive, high-precision linear and rotary axes, using high-resolution grating ruler and high-precision encoder position feedback to achieve full closed-loop control, faster speed, higher accuracy, good sealing characteristics, core components can be used for life, and operation and maintenance costs are lower.

5. Pipe clamping and feeding precision fixture design: precise fixtures and pneumatic components are used to control the clamping and automatic feeding of pipe materials, with precise and reliable movements. The processing process is fully automated, capable of continuously cutting the entire pipe and multiple supports, supporting multiple clamping methods and adaptive pipe materials.

6. Compatible with both dry and wet cutting processes: the entire machine is designed for sealing, combined with a waterproof splashing module, and has functions such as receiving workpieces and preventing splashing. It provides the best processing solution for producing metal supports of various pipe diameters and lengths.

7. Pipe support state adjustment function: The special modular design of the pipe feeding support device avoids disturbance of the pipe during the feeding process. Equipped with the function of coarse and fine adjustment of the front, back, top, and bottom positions of the pipes, it maximizes the avoidance of distortion and deformation of the pipes during the feeding process.

8. Auto focus function: The laser cutting head automatically focuses, eliminating the need to adjust the focal length multiple times.

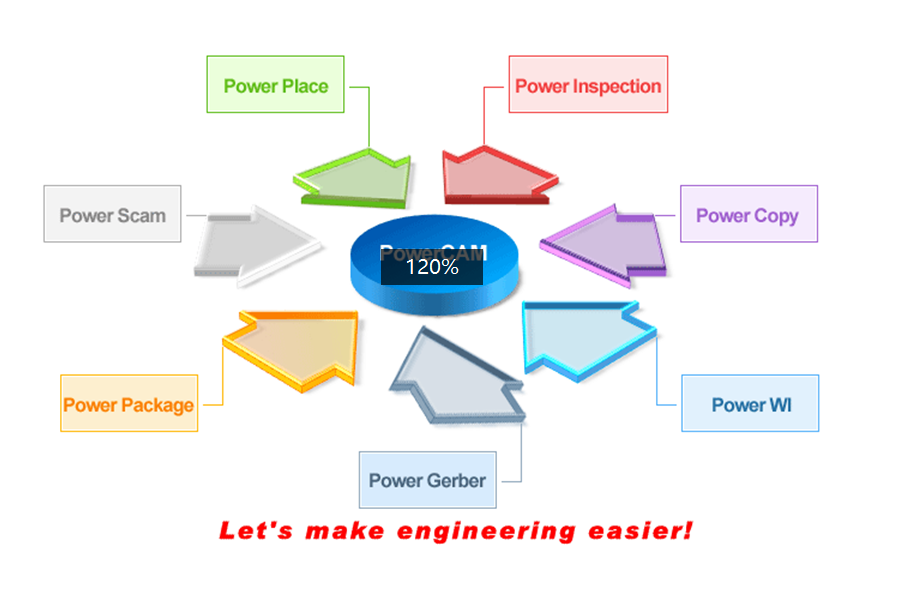

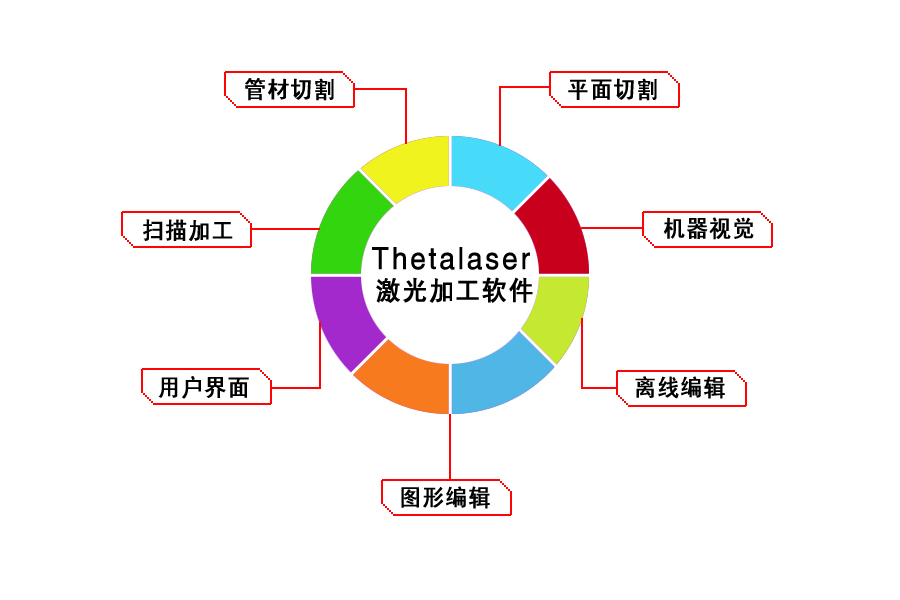

9. A software system with independent intellectual property rights: The intelligent laser micro processing application platform ThetaLaser, with a friendly interface, powerful functions, and simple operation.

Performance characteristics:

1. Compatible with multi brand fiber lasers: Suitable for high-performance fiber lasers of different brands and types, suitable for processing metal supports of various pipe diameters and lengths, with highly reliable and stable cutting quality.

2. Compatible with various laser cutting heads: suitable for laser cutting heads with different performance levels, including high, medium, and low, to meet various customer needs, while also being able to quickly switch between various laser cutting heads. Equipped with a CCD camera head, it has functions such as monitoring the status of the processing area, spot quality, and animation recording during the cutting process.

3. Natural granite platform design: Adopting a column structure, both the platform and columns use natural granite, and all axis systems are directly installed on the natural granite reference plane, with high accuracy and good stability.

4. Design of precision two-dimensional motion platform: Equipped with direct drive, high-precision linear and rotary axes, using high-resolution grating ruler and high-precision encoder position feedback to achieve full closed-loop control, faster speed, higher accuracy, good sealing characteristics, core components can be used for life, and operation and maintenance costs are lower.

5. Pipe clamping and feeding precision fixture design: precise fixtures and pneumatic components are used to control the clamping and automatic feeding of pipe materials, with precise and reliable movements. The processing process is fully automated, capable of continuously cutting the entire pipe and multiple supports, supporting multiple clamping methods and adaptive pipe materials.

6. Compatible with both dry and wet cutting processes: the entire machine is designed for sealing, combined with a waterproof splashing module, and has functions such as receiving workpieces and preventing splashing. It provides the best processing solution for producing metal supports of various pipe diameters and lengths.

7. Pipe support state adjustment function: The special modular design of the pipe feeding support device avoids disturbance of the pipe during the feeding process. Equipped with the function of coarse and fine adjustment of the front, back, top, and bottom positions of the pipes, it maximizes the avoidance of distortion and deformation of the pipes during the feeding process.

8. Auto focus function: The laser cutting head automatically focuses, eliminating the need to adjust the focal length multiple times.

9. A software system with independent intellectual property rights: The intelligent laser micro processing application platform ThetaLaser, with a friendly interface, powerful functions, and simple operation.

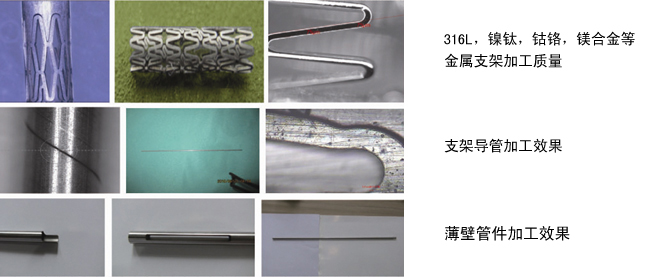

The main application scope of the product:

· Coronary medical stents;

· Heart valves;

· Hypotubes;

· High precision tube;

Technical specifications

|

Equipment model |

TLS-HT1330 |

|

Process Performance |

|

|

Maximum operating speed |

300mm/s (X); 600rpm( θ ) |

|

Still in the seminal position |

±2µm(X);±25arcsec(θ);±3µm(Z) |

|

Repetitive or precise |

±0.3µm(X);±4arcsec(θ);±0.5µm(Z) |

|

Related to processing work |

|

|

Type of pipe material |

Stainless steel, nickel titanium alloy, cobalt chromium alloy, magnesium alloy, pure iron and other metal pipes |

|

Pipe length |

<2500mm |

|

Pipe thickness up |

0~0.6mm±0.01 |

|

pipe diameter |

0.1~8.0mm±0.01 |

|

ambient temperature |

23±3℃ |

|

Environmental humidity |

20%~70%RH (No condensation) |

|

Clear boundary length |

0~300mm |

|

Remaining length |

70mm(Dry cutting),130mm(Wet cutting) |

|

Laser related |

|

|

Laser type |

Optical fiber laser |

|

power |

150W(Average power),1500W(maximum power) |

|

Laser wavelength |

1064nm±10nm |

|

Laser frequency |

Single pulse – 170 KHz |

|

Beam quality |

M²<1.1 |

|

Power stability |

<1% |

|

Compatible file format |

|

|

Compatible file format |

Gerber, DXF, HPGL, Sieb&Meyer, Excellon, OBD++, PCB,cam |

|

Water, electricity, and gas related |

|

|

source |

220VAC±10%, 50/60Hz |

|

Compressed air pressure |

0.8Mpa~1.0Mpa |

|

Process gas pressure |

<25bar |

|

Ground return |

1000Kg/㎡ |

|

The size to weight ratio of the above equipment |

|

|

Appearance specifications(L×W×H) |

2175mm×1550mm×761mm |

|

weight |

approx.1500Kg |

Sample images and software interface: