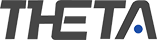

TLS-G8200 ultraviolet laser cutting drilling machine

Performance characteristics:

1. High performance ultraviolet laser: Using a semiconductor pump laser with high beam quality, high peak power, narrow pulse width, and high pulse stability, it is a "cold" processing method that can ensure processing quality and stability.

2. Optimized optical system design: low power loss, small focusing spot size, high laser beam quality, ensuring processing accuracy, and automatic focusing.

3. Precision two axis platform and fully closed loop CNC system: Adopting imported high-precision linear motion modules and control modules to ensure high-precision positioning and repetitive accuracy of the equipment.

4. CCD image positioning: The height of the laser processing reference point coincides with the design document reference point.

5. Natural granite machine: Reduce the inertial vibration generated by the starting, stopping, and accelerating processes of the workbench, while maintaining the stability of the machine temperature.

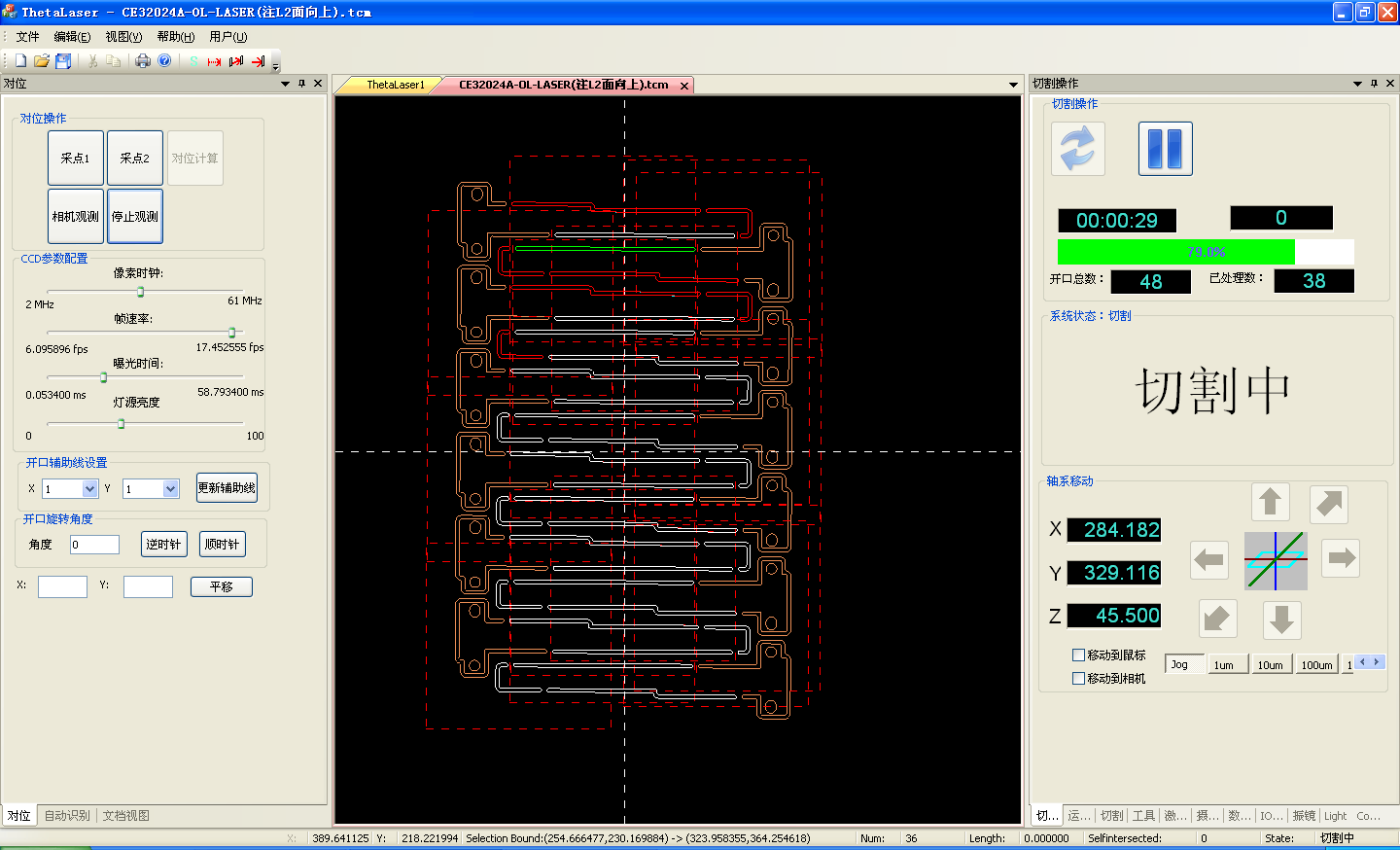

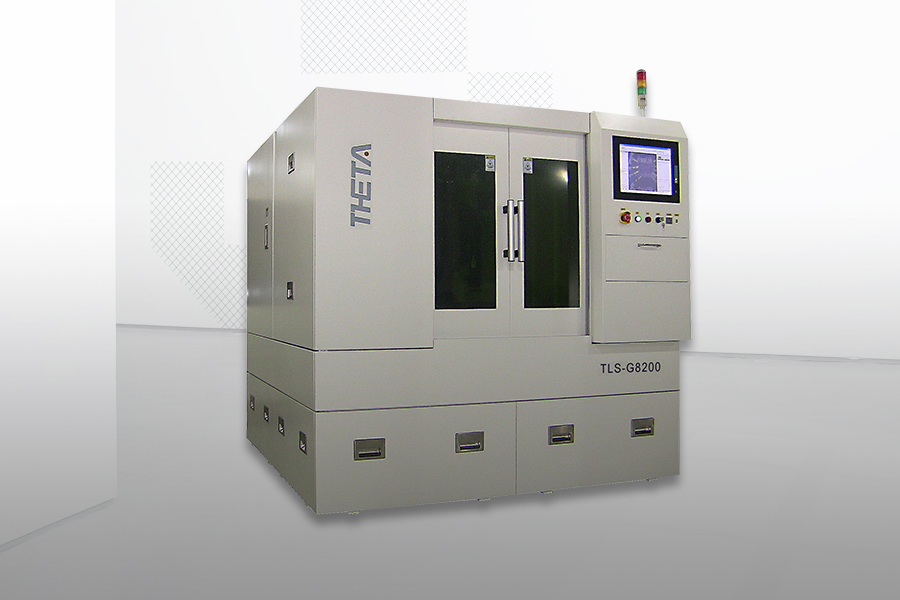

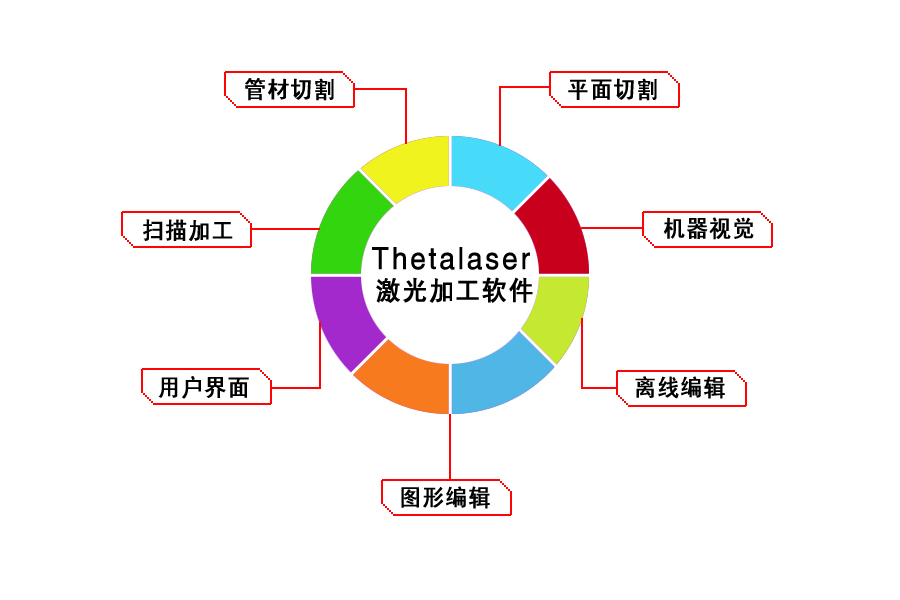

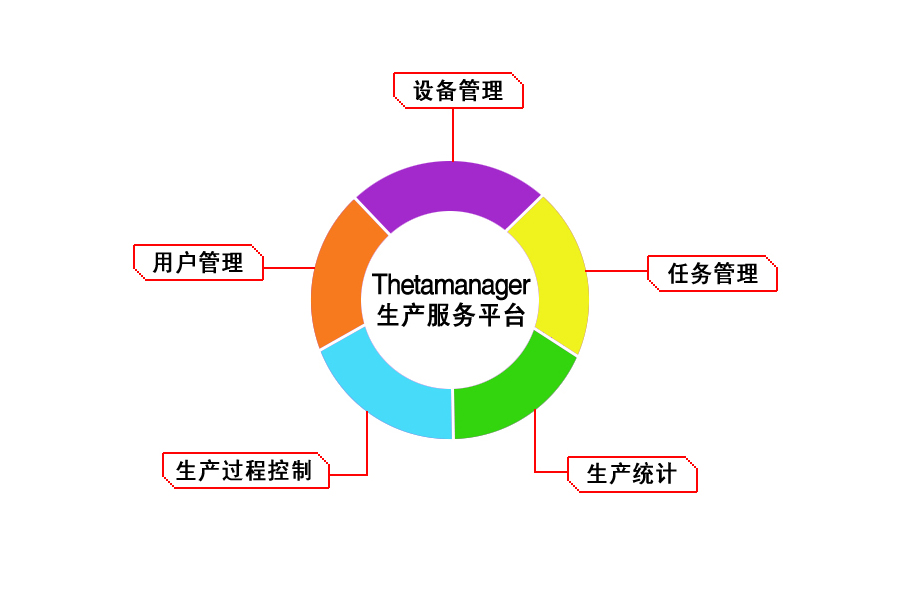

6. Software system with independent intellectual property rights: The intelligent laser micro processing application platform ThetaLaser is a laser micro processing platform developed on the basis of PowerCAM, with a friendly interface, powerful functions, simple operation, and compatibility with almost all design file formats.

7. Style (Option): UV laser cutting machine, UV laser drilling machine, UV laser cutting drilling machine.

Performance characteristics:

1. High performance ultraviolet laser: Using a semiconductor pump laser with high beam quality, high peak power, narrow pulse width, and high pulse stability, it is a "cold" processing method that can ensure processing quality and stability.

2. Optimized optical system design: low power loss, small focusing spot size, high laser beam quality, ensuring processing accuracy, and automatic focusing.

3. Precision two axis platform and fully closed loop CNC system: Adopting imported high-precision linear motion modules and control modules to ensure high-precision positioning and repetitive accuracy of the equipment.

4. CCD image positioning: The height of the laser processing reference point coincides with the design document reference point.

5. Natural granite machine: Reduce the inertial vibration generated by the starting, stopping, and accelerating processes of the workbench, while maintaining the stability of the machine temperature.

6. Software system with independent intellectual property rights: The intelligent laser micro processing application platform ThetaLaser is a laser micro processing platform developed on the basis of PowerCAM, with a friendly interface, powerful functions, simple operation, and compatibility with almost all design file formats.

7. Style (Option): UV laser cutting machine, UV laser drilling machine, UV laser cutting drilling machine.

The main application scope of the product:

· Splitting and drilling of flexible circuit boards, rigid circuit boards, rigid flexible integrated circuit boards, and chip packaging substrates

· Splitting processing of rigid and flexible circuit boards with installed components

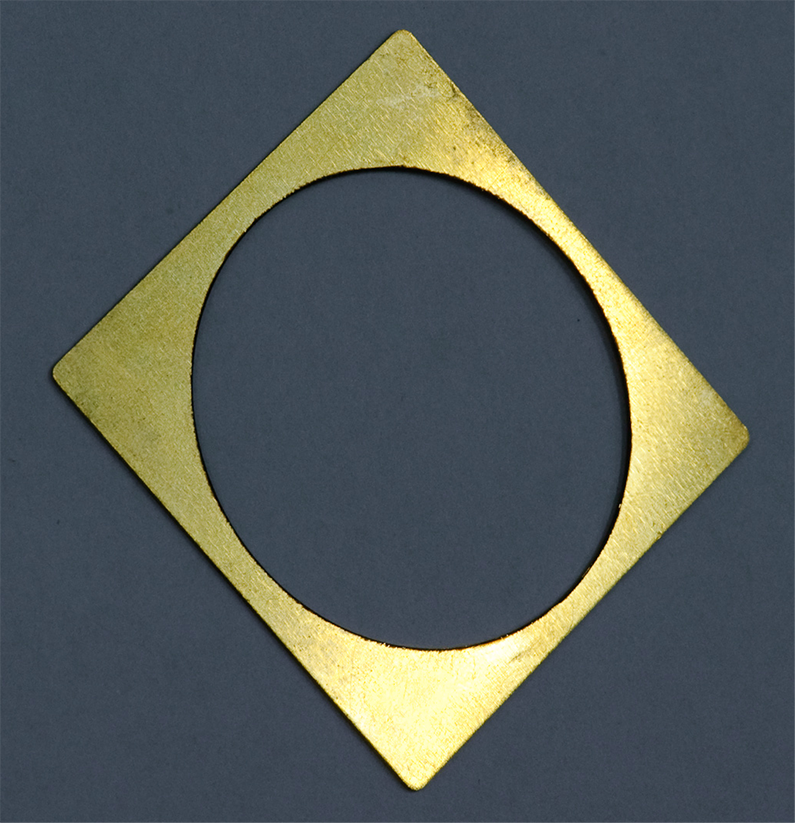

· Precision cutting and scoring of ceramics with a thickness of less than 2.0mm

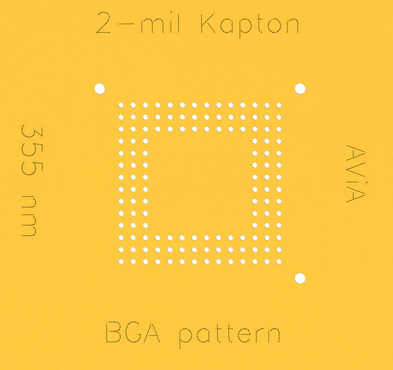

· Precision cutting and drilling of thin copper foil, pressure sensitive adhesive sheet (PSA), PP, acrylic sheet, polyimide coating film, etc

· Precision cutting of ITO film, glass, organic film, special metal sheet, silicon material, sapphire, etc

· Support roll to roll processing method

Technical specifications:(3Sigma)

|

model |

TLS-G8200 |

|

machine range |

500mm×500mm×50mm(customizable) |

|

X/Y platform positioning accuracy |

<±3µm |

|

X/Y repetition accuracy |

±1µm |

|

Maximum operating speed of X/Y platform |

800mm/s |

|

laser power |

10W(Standard configuration) |

|

wavelength |

355nm |

|

Laser Frequency |

30-130KHz |

|

ambient temperature |

23±3oC |

|

ambient humidity |

20%~70%RH(No condensation) |

|

Compatible file formats |

Gerber, DXF, HPGL, Sieb&Meyer, Excellon, PCB |

|

INPUT VOLTAGE |

three-phase 380VAC±10%, 50/60Hz, 15A |

|

Electric power consumption |

3.0KW |

|

Compressed air pressure |

0.7~0.8MPa |

|

Machine size (length × wide × High) |

2125mm×1840mm×1800mm |

|

machine weight |

3500Kg |

|

producer |

China |

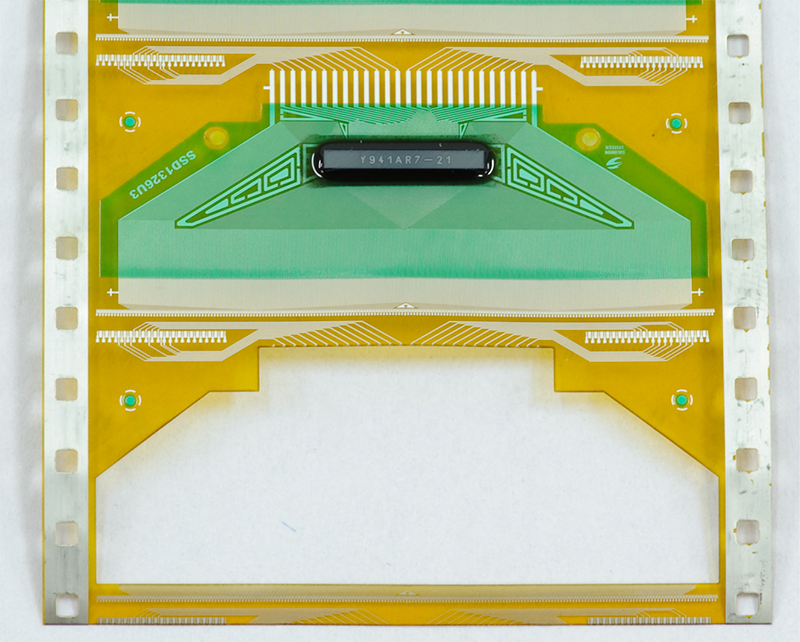

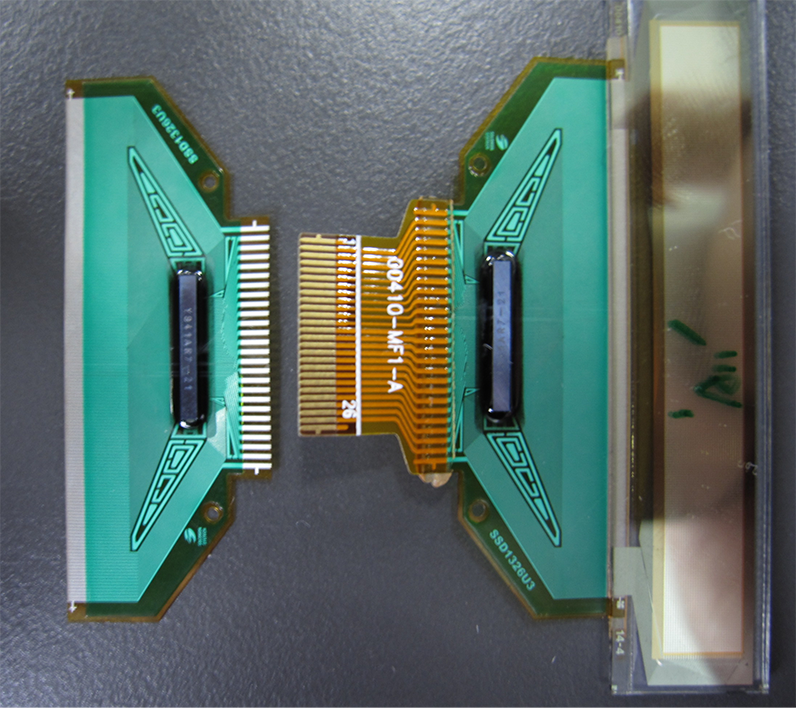

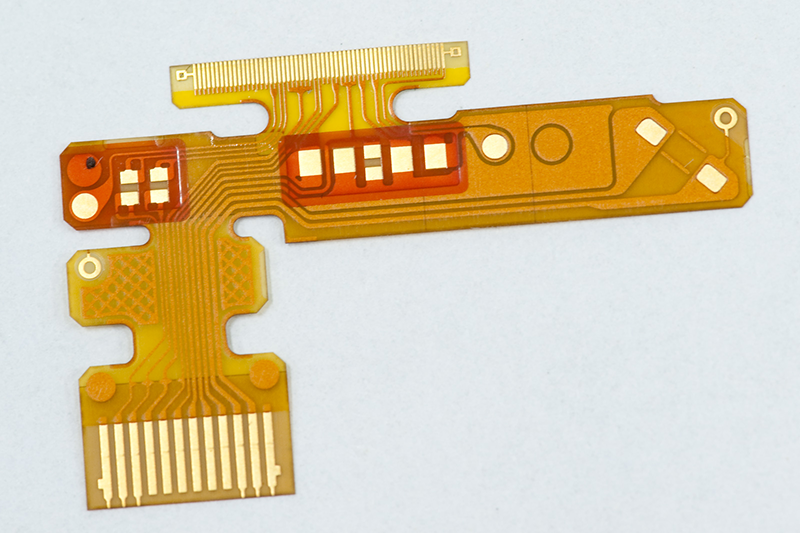

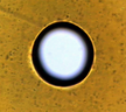

Sample image:

|

|

|

|

|

|

|

|