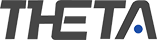

TLS-G8600 Precision Component Laser Cutting Machine

Performance characteristics:

1. High performance fiber laser: Adopting a fiber laser with high beam quality and high electro-optical conversion efficiency to ensure cutting quality

Reliability and stability.

2. High precision motion platform: The machine base is made of natural granite, and the gantry adopts a dual drive movable beam structure, with high accuracy and good stability. Adopting high-precision and high rigidity special guide rails, high acceleration linear motors, and high-precision encoder position feedback, it solves the problems of insufficient rigidity, idle return, and dead zone in traditional servo motor and ball screw structures, resulting in faster speed and higher accuracy. Key components can be used for life, with lower operating and maintenance costs.

3. Cable system: long service life, high reliability, smooth movement, good electromagnetic compatibility; It solves the problems of poor electromagnetic compatibility, loud noise, dust, abrasion, etc. of the traditional drag chain system.

4. Autofocus function: During the processing, autofocus is performed without the need for additional focus adjustment.

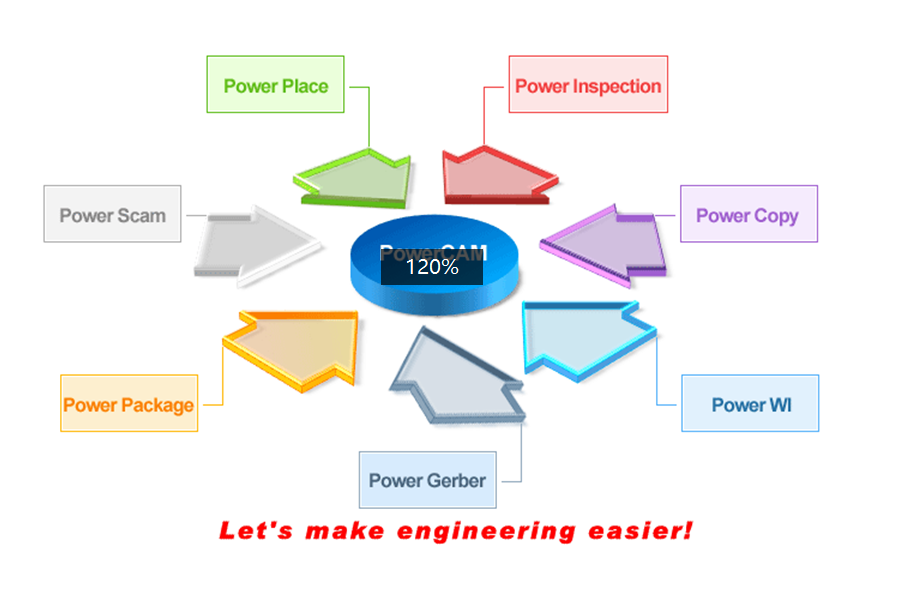

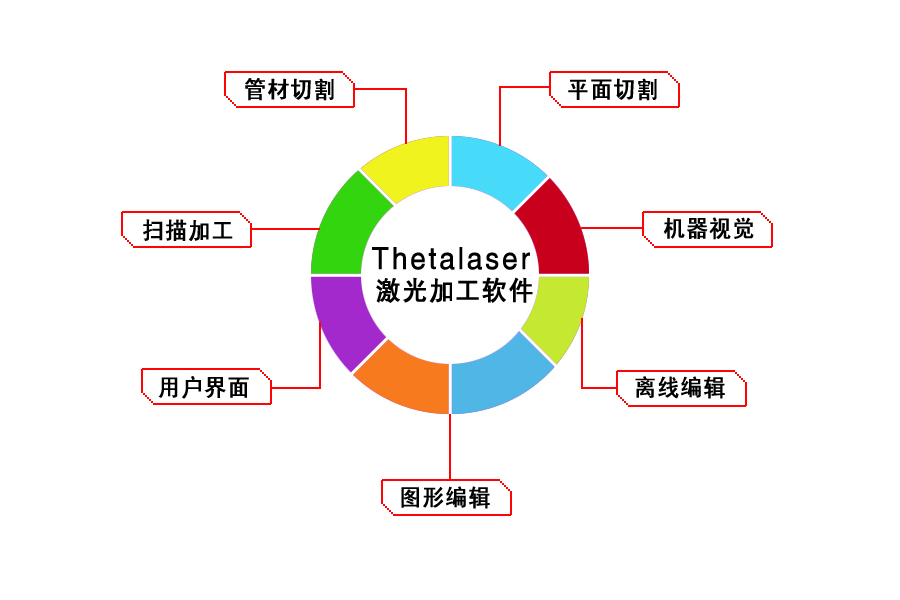

5. A software system with independent intellectual property rights: The intelligent laser micro processing application platform ThetaLaser, with a friendly interface, powerful functions, simple operation, and compatibility with almost all design file formats.

6. Power balance control (option): With a unique power balance fuzzy logic control method, it greatly improves cutting quality.

7. Online detection function (option): Equipped with online detection and measurement functions to ensure cutting quality.

8. Support for automatic feeding (option): Supports automatic feeding and alignment, reducing non laser cutting time and greatly improving production efficiency.

Performance characteristics:

1. High performance fiber laser: Adopting a fiber laser with high beam quality and high electro-optical conversion efficiency to ensure cutting quality

Reliability and stability.

2. High precision motion platform: The machine base is made of natural granite, and the gantry adopts a dual drive movable beam structure, with high accuracy and good stability. Adopting high-precision and high rigidity special guide rails, high acceleration linear motors, and high-precision encoder position feedback, it solves the problems of insufficient rigidity, idle return, and dead zone in traditional servo motor and ball screw structures, resulting in faster speed and higher accuracy. Key components can be used for life, with lower operating and maintenance costs.

3. Cable system: long service life, high reliability, smooth movement, good electromagnetic compatibility; It solves the problems of poor electromagnetic compatibility, loud noise, dust, abrasion, etc. of the traditional drag chain system.

4. Autofocus function: During the processing, autofocus is performed without the need for additional focus adjustment.

5. A software system with independent intellectual property rights: The intelligent laser micro processing application platform ThetaLaser, with a friendly interface, powerful functions, simple operation, and compatibility with almost all design file formats.

6. Power balance control (option): With a unique power balance fuzzy logic control method, it greatly improves cutting quality.

7. Online detection function (option): Equipped with online detection and measurement functions to ensure cutting quality.

8. Support for automatic feeding (option): Supports automatic feeding and alignment, reducing non laser cutting time and greatly improving production efficiency.

The main application scope of the product:

Precision metal component cutting

Precision Metal Parts Half Carving

Technical specifications:(3Sigma)

|

model |

TLS-G8600 |

|

Processing speed |

50mm/s |

|

X/Y axis travel |

600mm×800mm,500mmx500mm,975mmx1100mm(customizable) |

|

machine range |

600mm×800mm(customizable) |

|

Maximum mesh frame size that can be loaded |

750mm×1000mm |

|

Maximum metal sheet size that can be loaded |

600mm×800mm |

|

Metal sheet thickness |

0.02~0.6mm |

|

positioning accuracy |

±3µm(X-axis and Y-axis) |

|

repeatability |

±1µm(X-axis and Y-axis) |

|

wavelength |

1070nm |

|

Laser Frequency |

0~50KHz |

|

ambient temperature |

23±3oC |

|

ambient humidity |

20%~70%RH(No condensation) |

|

file format |

DXF,Gerber class |

|

INPUT VOLTAGE |

220VAC±10%, 50/60Hz, 10A,single phase |

|

Electric power consumption |

1.5KW |

|

Compressed air pressure |

<1.5MPa(15Kg) |

|

Machine size (length × wide × High) |

1400mm×1750mm×1450mm |

|

machine weight |

2500Kg |

|

producer |

China |

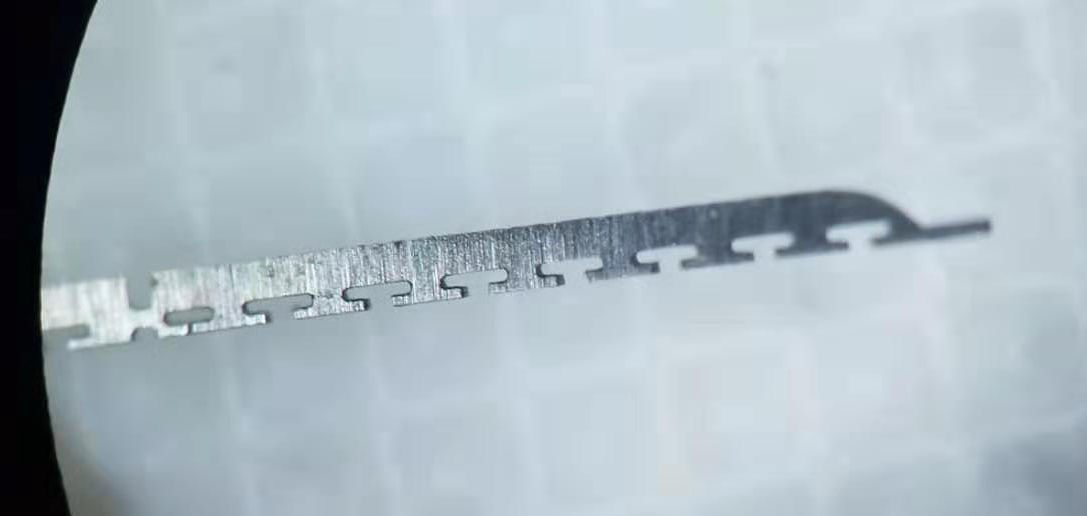

Sample image: