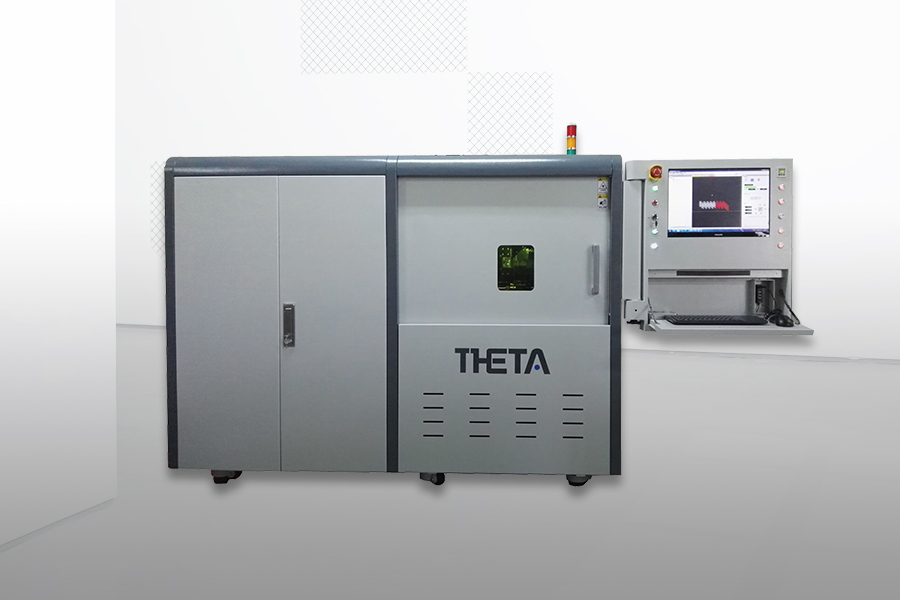

TLS-HT1200 femto second laser stent cutting machine

Performance characteristics:

1. Compatible with many brands of ticket-second lasers: suitable for high-end ticket-second lasers of different sizes and lengths, suitable for processing non-metallic bottles of different sizes and lengths. Clear boundaries are essential to ensure reliable and stable quality.

2. Compatible with various laser delineation heads: Suitable for delineation heads with high, medium, and low performance lasers, meeting customer needs. Adjusting the optical path design can achieve fast switching between different laser delineation heads. Equipped with a CCD camera head, it has functions such as monitoring the status of the processing area, quality of the light spot, and willingness to record videos during the boundary drawing process.

3. The design of the natural granite podium: the column structure is adopted. The platform and columns are all natural granite, and all shafts are directly installed on the natural granite datum plane. Although it is high and stable.

4. Precision 2D motion podium design: it is equipped with straight axis and rotary axis on the drive and high-precision, and uses high-resolution grating ruler and high-precision upper numbering device position feedback to achieve full closed-loop control. It has faster speed, higher precision, good sealing characteristics, life-long use of core components, and lower lucky maintenance costs.

5. The design of precision fixtures for tube attraction and feeding: The use of precision fixtures and pneumatic control for tube material attraction is more precise and reliable than automatic material feeding. The processing process is fully automated, capable of continuously demarcating the entire bottle of tubing and one bottle, supporting various clamping methods and adaptive tubing.

6. Pipe support state adjustment function: The special modular design of the pipe feeding support device avoids disturbance of the pipe during the feeding process. Equipped with the function of coarse and fine adjustment of the front, back, and up and down positions of the prepared pipe, it maximally avoids twisting and deformation of the pipe during the feeding process.

7. Auto focus function: The laser clears the boundary and automatically focuses, eliminating the need to adjust the focus at once.

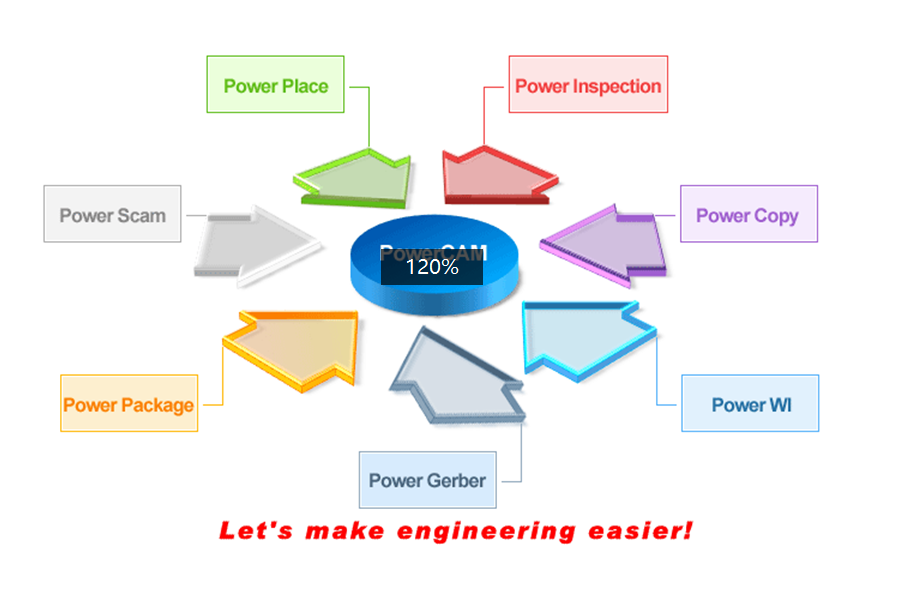

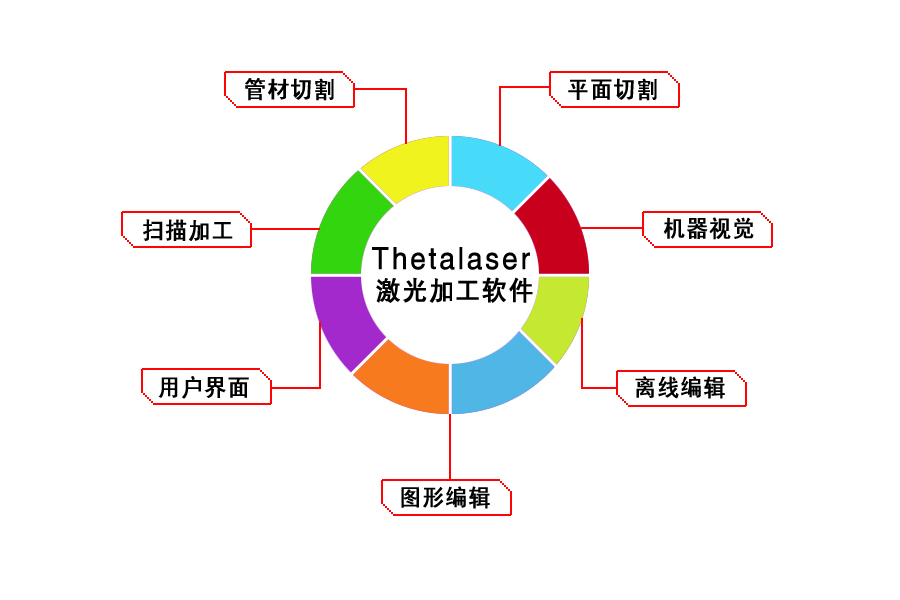

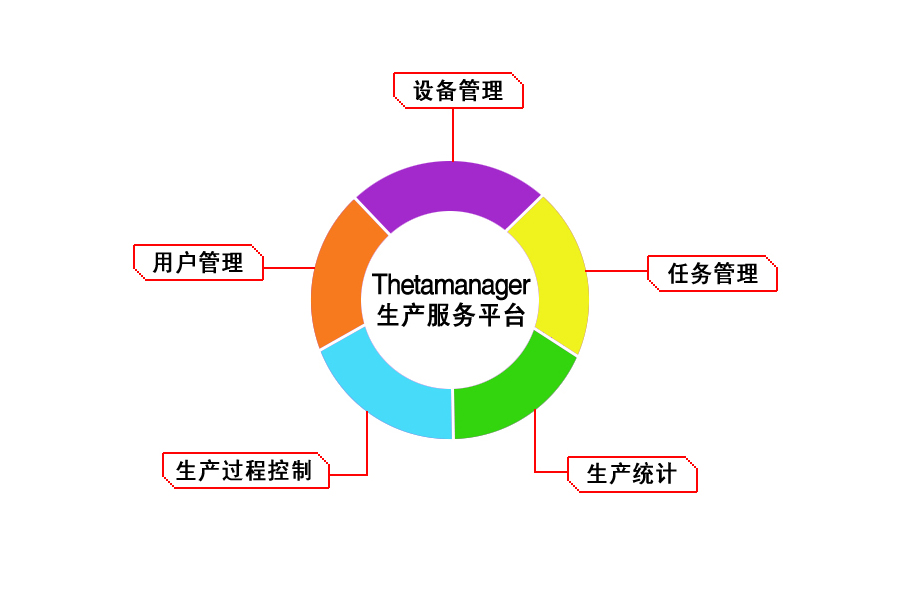

8. The software system with independent intellectual property rights: ThetaLaser, the podium of intelligent laser micro machining application, has complete processing parameters and status records, supports docking with customers' intelligent manufacturing systems, has a good interface, powerful functions, and simple operation.

The main scope of use of the product:

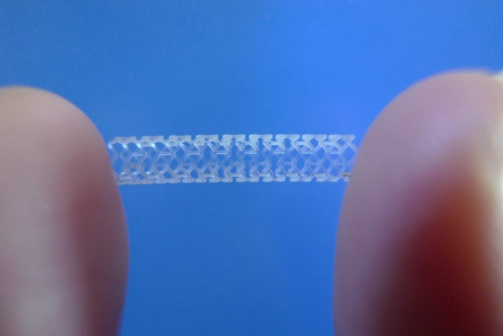

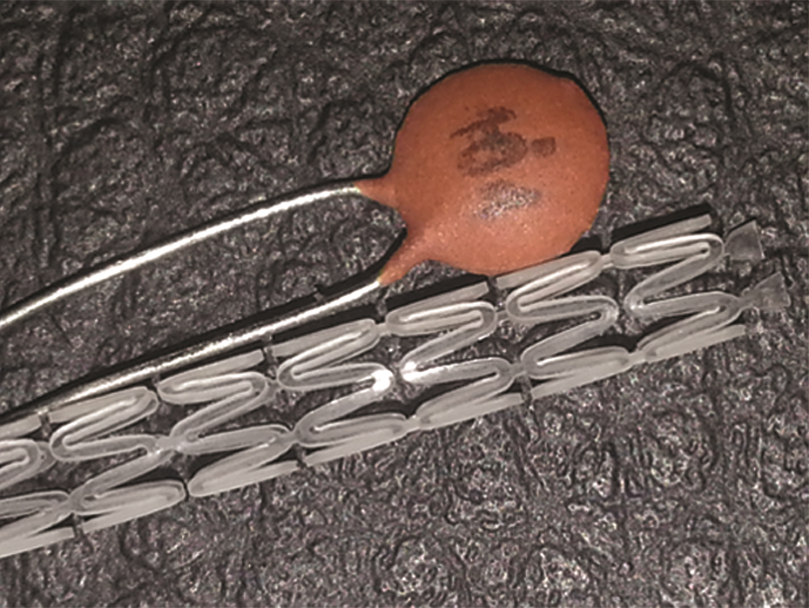

· Biorseorbable stents;

· Polymer tubing ;

· Surface modification;

Technical specifications:

|

The above equipment is available for negotiation |

TLS-HT1200 |

|

Process performance |

|

|

Maximum Lucky Speed |

2000mm/s (X-axis); 600rpm( θ Axis) |

|

Repetitive or precise |

± 0.2 µ m (X-axis); ± 3arcsec( θ Axis); ± 0.5 µ m (Z-axis) |

|

Still in the seminal position |

± 1 µ m (X-axis); ± 15arcsec( θ Axis); ± 3 µ m (Z-axis) |

|

Minimum clearance boundary seam width one |

10µm |

|

Related to processing work |

|

|

Type of pipe material |

Polymer polymerization does not allow non-metallic pipes; |

|

Pipe length |

<3M |

|

Pipe thickness up |

0~0.8mm |

|

pipe diameter |

0.2~18mm |

|

Processing scope |

0~200mm(Singular continuous processing) |

|

Remaining fabric length |

50mm |

|

Laser related |

|

|

Laser type |

Optical fiber, femtosecond, picosecond laser |

|

wavelength |

532nm±10nm |

|

frequency range |

<500KHz |

|

Beam quality |

M2<1.5 |

|

Power stability |

<± 3% (8 consecutive hours of good luck) |

|

Compatible file format |

|

|

Compatible file format |

DXF、Gerber |

|

Water, electricity, and gas related |

|

|

source |

Three photos 380VAC ± 10%, 50/60Hz |

|

Compressed air pressure |

0.6Mpa~0.8Mpa |

|

Process gas pressure |

<2Mpa (<20Kg) |

|

Environmental requirements |

|

|

ambient temperature |

23±3oC |

|

Environmental humidity |

20%~70%RH(No condensation) |

|

Ground return |

1000Kg/M2 |

|

The size to weight ratio of the above equipment |

|

|

Appearance specifications |

2175mm×761mm×1550mm |

|

weight |

About 1500kg |

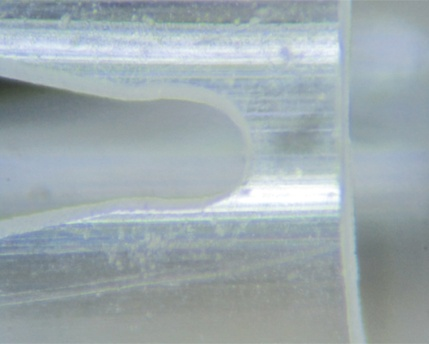

Sample image: